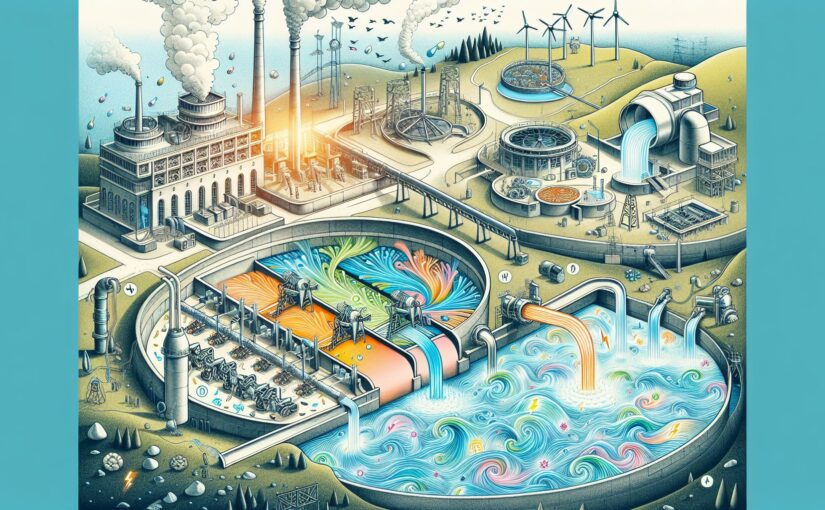

In the age of climate change and scarce freshwater resources, the treatment of wastewater has taken on an increasingly important role. Not only is it a means for cleaning and recycling water, but it can also serve as an unexpected source of renewable energy. In fact, the potential for energy generated from wastewater is enormous and underutilized. This exciting topic will be the focus of our discussion today.

The Unseen Energy

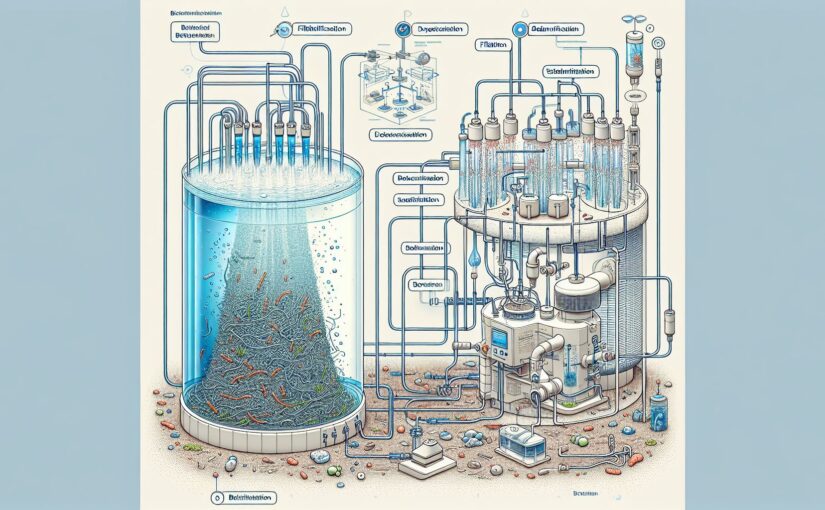

So how exactly can wastewater generate energy? It all comes down to microbial reactions and the breakdown of organic matter present in the wastewater. According to a study by researchers at Ghent University, bacteria within wastewater can anaerobically digest this organic matter and produce biogas, a mixture of methane and carbon dioxide[^1^].

Role of Microbial Fuel Cells

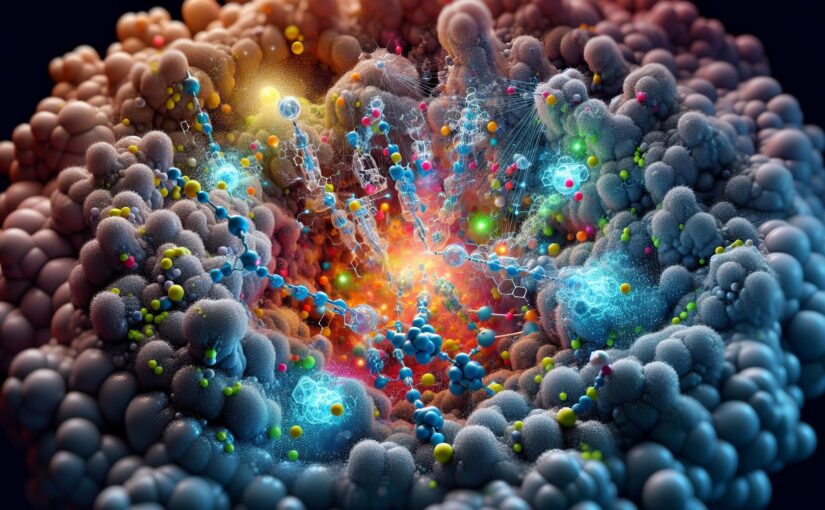

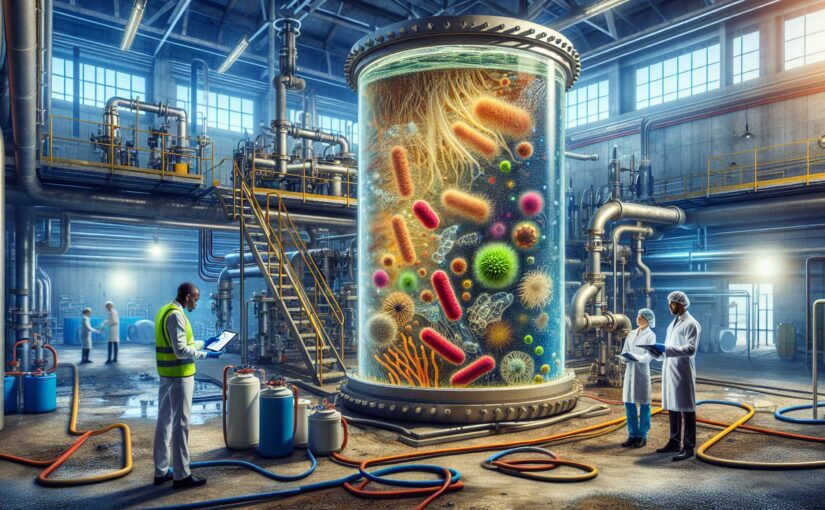

A central player in this process is something known as a microbial fuel cell (MFC). These MFCs work by allowing bacteria to oxidize organic matter and transfer the resulting electrons to a terminal electron acceptor at the bioanode. The electrons then travel to the biocathode, where they combine with protons and oxygen to form water. This flow of electrons, in turn, creates an electrical current[^2^].

As discussed in a study by an esteemed scientist, Bruce Logan, at Pennsylvania State University, this energy can then be harvested for use. On a small scale this might include powering sensors or small electronic devices. However, on a larger industrial scale it has the potential to contribute to a grid[^3^].

Future of Wastewater Treatment

Beyond providing a source of renewable energy, this process also has the added benefit of potentially streamlining wastewater treatment. In traditional methods, energy is required to aerate the wastewater, but in this process, it’s the other way around. Not only could this save on energy costs, it could also help to reduce the carbon footprint of an industry notorious for its high energy use.

Clearly, there is significant scope for improvement in our current wastewater treatment processes, and the concept of generating energy from wastewater provides numerous exciting opportunities. This is one technology that certainly has the potential to make a big splash!

References

[^1^]: Clauwaert, P. et al. (2007). Minimizing losses in bio-electrochemical systems: the road to applications. Applied Microbiology and Biotechnology, 77(3), 903–913. Link

[^2^]: Rabaey, K. et al. (2010). Microbial fuel cells for bioenergy generation: from fundamentals to application. Journal of Chemical Technology & Biotechnology, 85(5), 533–544. Link

[^3^]: Logan, B. E., & Regan, J. M. (2006). Electricity-producing bacterial communities in microbial fuel cells. Trends in microbiology, 14(12), 512-518. Link